The Fan Filter Unit, also called FFU, is an air supply and filtration unit in modular end. The FFU draws air on top and filters it through a HEPA (High Efficiency Particulate Air Filter). Then the filtered clean air will be sent out evenly at a pre-set speed over the air outlet. It is generally installed in the clean room ceiling for maximum efficiency and also to increase the flexibility of airflow.

Technical Parameter

Model Parameter | FFU-HA24 | FFU-HA23 | FFU-HA22 |

| Overall dimensions (mm) | 1175×575×340 | 1175×1175×340 | 575×575×340 |

| Surface wind speed (m / s) | 0.35~0.45 | 0.35~0.45 | 0.35~0.45 |

| Noise db (A) | 48~53 | 48~53 | 48~53 |

| HEPA filtration efficiency | ≥99.99(φ0.3μm) | ||

| HEPA filter specifications | 1170×570×70 | 870×570×70 | 570×570×70 |

| Power (Hz) | AC,220V/50Hz | ||

| Power (W) | 110-220 | 100-180 | 90-150 |

| Machine residual pressure (Pa) | 50-130 | ||

INTRODUCTION

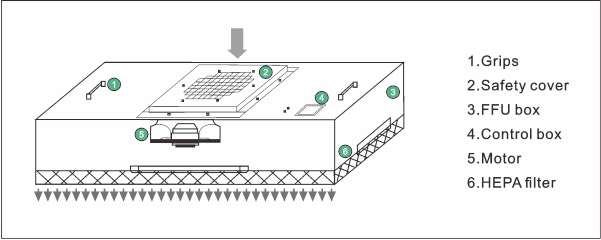

The FFU consists of four main parts:

1)Box: its material mainly adopts galvanized aluminum alloy coated steel, aluminum alloy and stainless steel. Function one is to support the fan and air guide ring, and function two is to support the deflector;

2)Deflector: it’s an airflow balance device, located in the box and under the fan.

3)Fan: There has three types of single-phase Alternative Current (AC/1Phase), Direct Current (DC/1Phase) and triple-phase Alternative Current.

4)Control Unit: it can achieve remote control by control software, computer, control gateway and network lines.

Classification of FFU:

1.According to the box size: customized

2.According to the material: there are standard coated steel plates (including galvanized, aluminized zinc, plastic spraying, etc.); stainless steel plates; aluminium plates (aluminium alloy plates); and other materials.

3.According to the motor: AC motor and brushless DC motor.

4.According to the static pressure of the unit: it can be divided into standard static pressure and high static pressure.

5.According to the filter efficiency: it can be divided into high efficiency filter; ultra high efficiency filter; some units have coarse efficiency pre-filter at the entrance.

FFU and traditional air conditioning units:

Traditional purified air conditioning systems mainly adopts centralized air supply, i.e. air processing devices (heater, cooler, humidifier, coarse and medium efficiency filter, etc.) and fans are set up centrally in the air conditioning room, and high efficiency filters are arranged at the end of the system, connecting the air processing devices to the clean room through centralized air supply and return ducts. The biggest disadvantage of this unit is that it is less adaptable and almost impossible if the cleanliness level needs to be adjusted. In contrast, in the Fan Filter Unit (FFU), the air is sent from the FFU to the clean room, and then get back from return air static pressure box to the supply air static pressure box through two sides of the mezzanine. A dry table cooler is set up in the mezzanine to deal with the load in the clean room. The fresh air processor can be centrally located in the air conditioning room, and the air will be sent directly to the air supply static pressure box after processed.

Compared with the traditional centralized air supply unit, FFU has:

(1)Flexible system, can be adjusted at any time

The size of the FFU is arranged in the Ceiling Grid module (e.g. 1200 x 600) and, due to its special node configuration, can be adjusted at any time to suit the production layout. If the cleanliness of production area needs to be adjusted, this can be achieved by increasing or decreasing the number of FFU or changing the circulating air volume. This is almost impossible for the traditional centralized air supply purification systems. The adjustment only affects the in the renovated area but almost no effect on the non-renovated.

(2)Stable air output

The FFU has its own fan and control unit, so it is easy to achieve a stable air flow, while the centralized air supply system relies on the air valve to adjust the flow.

(3)Economical

The cost of the FFU air supply system is slightly higher than that of the centralized air supply unit actually. However, in a high-level clean room, the height of the technical mezzanine required for FFU is lower than that of centralized air supply. So the civil construction cost of the FFU is reduced and then the total cost will finally be lower than the another.

(4)Negative pressure sealing

The static pressure box of FFU is negative pressure, so it is relatively easy to seal the air outlet installation, and even if there is leakage, the air will flow from clean room to the static pressure box, which will not cause contamination to the clean room.

Contact: Joyce

Phone: +86 14792975586

E-mail: sales1@dongritc.com

Whatsapp:+86 14792975586

Add: No.499jinsheng Road,Jinjiaba,Wujiang District,Suzhou City,Jiangsu Province

We chat