Purification doors generally refer to the door that are easy to clean, anti-bacterial and have excellent air tightness. They are suitable for various hospital constructions, biomedical laboratories, food and beverage processing factories, electronic plants and other occasions with high air tightness requirements.

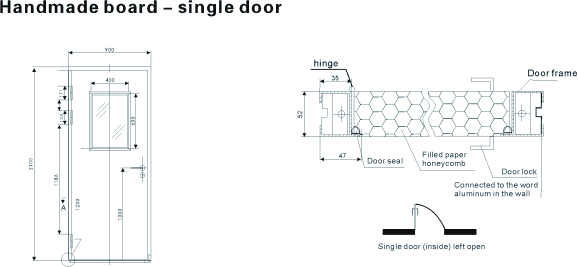

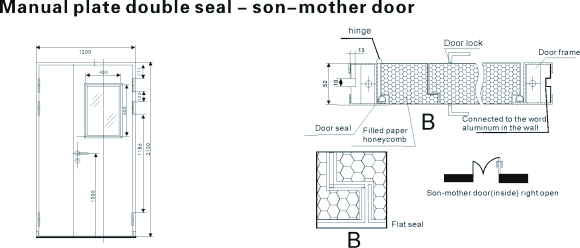

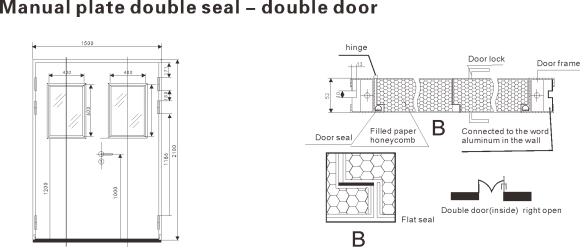

| Model Parameter | Single door | Double door | unequal double door |

| Steel plate thickness (mm) | 0.8-1.2 | ||

| Door thickness (mm) | 50 | ||

| Door size (W * Hmm) | 900*2100 | 1500*2100 | 1200*2100 |

| Hole size (W * Hmm) | 970*2130 | 1570*2130 | 1270*2130 |

According to the standard of clean room decoration: no dust generation,, hard to accumulate dust, corrosion resistance, impact resistance, no cracking, moisture and mould resistance, easy to clean, energy saving, environmental protection,etc., purification door must have a good overall performance, with advantages of flat surface, high compressive strength, corrosion resistance, little accumulating dust, no dust generation, easy to clean, and so on. It also has a simple and fast installation, as well as a good air tightness.

Therefore, it is of basic advantages for a high-quality purification door to be easy-cleaning, anti-bacterial and have good air tightness.

Made by SPCC

Door frame adopts SPCC 1.5mm

Door panel adopts SPCC1.0mm

Product description: After the frame is formed, it is unified with the thickness of the 50mm manual plate wall to meet the characteristics of the clean room with less angle and easy cleaning.

According to the material and use, it can be divided into purification steel door, all stainless steel purification door, medical airtight door, and purification rolling shutter door.

1.Purification steel door

The panels and frames of purification doors are made of high-quality Steel Plate Cold Commercial (SPCC), and core materials of paper and aluminium honeycomb or foam. The door frame and wall are kept in a same plane, with a sense of integrity. There are sealing strips on three sides and a sweeping strip at the bottom of the door, which meets the hygiene requirements for various industries. The doors are generally available as single, double and sub-doors.

Product features

Material: Steel Plate Cold Commercial (SPCC)

Configuration:

Frame: SPCC

Panel: SPCC

Windows: double-layer tempered glass window, generally using round corner, 400mm*600mm, round inside square outside or round corner customized

Core Material: fire retardant paper honeycomb, aluminium honeycomb or foam, electrostatic spray coating on the surface(color customized)

Hinge: 3 high strength stainless steel hinge

Lock: stainless steel “L” shape folding door lock

Other Accessories: stainless steel hinge, spherical press lock, Stainless steel separate lock, automatic dust bar, door closer, hardware fitting, etc.

2.Full stainless steel purification door

Full stainless steel purification door is made of paper honeycomb as core material and SUS304 stainless steel as plate, which has a smooth and bright surface and is hard to deform. Because paintings are not required, some harmful toxic gas will be avoided from air into the human body without using other oil paints. The purification door adopts high quality stainless steel hinges, which can highly resist the corrosion and extend its service life. Compared to steels, SUS304 has the same strength but stronger rust resistance and easier processing to harden, so it could have a large better strength by cold working. And SUS304 does not adhere to magnets as a kind of austenitic stainless steel .

Product features

Material: SUS304

Configuration:

Frame: SUS304

Panel: SUS304

Windows: double-layer tempered glass window, generally using round corner, 400mm*600mm, round inside square outside or round corner customized

Core Material: paper honeycomb

Lock: stainless steel “L” shape folding door lock

Other Accessories: stainless steel hinge, spherical press lock, Stainless steel separate lock, automatic dust bar, door closer, hardware fitting, etc.

3. Medical airtight door

The type of medical airtight door: generally classified by its structure. There are mainly 3 types: airtight, anti-radiation, airtight and anti-radiation.

The principle of medical airtight doors is to prevent direct convection between the isolated space and the outside air, building a certain negative pressure in the isolated space in order to make inner pressure less than the outside. As a result, the door will be closed tightly in the use of air pressure, so as to ensure its excellent sealing and impermeability and avoid outside pollution into the indoor environment.

The structure of airtight door:

1.The door panel is made of double-layer high-quality 304 stainless steel or 0.6mm high quality color coated coil, and retardant aluminium honeycomb as its core. If customer demands, it can also be made of casting double-layer carbon steel plate, with high temper painting over the surface, such as the installation in laboratories with radioactivity: the door needs to be lined with anti-radiation lead plate.

2. The door controller has a internal protection against over voltage, over current and over heat. It can be controlled with intelligent microcomputer, foot induction, contact-free hand sensor and remote control. It also has a automatic monitoring function which can adjust the time and speed of door and is easy to operate.

3. The high-efficiency motor operation owns a internal design of silent guide control. The hanger pulley is covered by special high-quality materials so as to lead a safe and reliable operation. The door will automatically return while running into obstacles or human body and other situations, to avoid hand pinched or other accidents.

4. The door is decorated by double-layer hollow thick tempered glass window, with 304 stainless steel anti-collision belt on the waist and aluminum alloy sealing profile or stainless steel one the edge. And the door machine cover is made of high-quality 304 stainless steel.

5. The door is equipped with high-precision and durable sliding rails, which can be directly assembled on the brick wall. The external equipment is easy to load, unload and debug. Because of the poor resistance of door pulley ,emergency opening could be light and convenient. Even a very small force can open and close it freely while power failure or other unexpected situations.

4、PVC fast rolling door

PVC (polyvinyl chloride) fast rolling door is a modern factory purification workshop channel door, specially for the workshop entrance and exit dust and air conditioning barrier, fast opening and closing, working efficiency and the overall environmental requirements. Purification workshop is a place where the cleanliness, temperature and humidity reach a certain standard. Therefore the products can be produced and manufactured in good environment. In order to prevent dust into the purification workshop, the partition of the clean room is generally made of color steel plate, and the access door is made of PVC material fast rolling shutter door. Now the use of PVC fast rolling shutter door in the purification workshop has become the standard configuration.

PVC fast rolling shutter door has been installed with an automatic switching system. Besides, the speed of operation is more than 0.6 meters per second, allowing for quick access for forklifts that often enter and exit the logistics channel door. This results in 70-90% efficiency in maintaining specific temperature and humidity levels in the workshop. Additionally, the fast rolling doors can also isolate most annoying and harmful insects. In conclusion, dust and odor isolation can keep the production workshop healthy and comfortable.

Because the purification workshop is a dust-free and closed workshop, in the face of frequent entry and exit personnel and vehicles, it is necessary to require the access door to meet the needs of quick switching. This helps to achieve the effect of dust prevention and sealing. Ensuring the coordination and unity of the environmental area in the production process of the workshop, the rolling shutter door greatly reduces the influence of external factors on the production environment.

Features:

The rolling shutter door has many functions such as thermal insulation, refrigeration, insect prevention, wind-proof and dust-proof performance, sound insulation, fire prevention, odor isolation, good sunlight and so on. What’s more, it is widely used in food, chemical industry, textile, electronics, supermarkets, freezing, logistics, warehousing and other places, can meet the logistics and clean places, and save energy, high-speed automatic closure, improve working efficiency, create a better working environment and other advantages.

Control Mode:

Manual push-button type

Manual cable type (long life cable switch)

Remote control (medium distance remote control)

Magnetic ring type (automatic induction of metal objects)

Remote control (medium distance remote control)

Magnetic ring type (automatic induction of metal objects)

Radar control(automatic sensing range of displaced objects)

Double-sided photoelectric (accurate sensing through the line of sight object)

Two doors interlock (controlled by PLC program)

Other ways can be through a variety of sensor signals into PLC or directly through the program setting.

Contact: Joyce

Phone: +86 14792975586

E-mail: sales1@dongritc.com

Whatsapp:+86 14792975586

Add: No.499jinsheng Road,Jinjiaba,Wujiang District,Suzhou City,Jiangsu Province

We chat